Each cell format is essential in battery analysis and improvement. Nonetheless, the info obtained from every format should be evaluated inside the boundaries outlined by its design and the scale of the examined electrodes. Uncritically extrapolating the efficiency of potential business large-area cells from information generated with smaller codecs usually overlooks points that turn out to be obvious solely throughout scaling up. When going to mass manufacturing, such assumptions can result in a considerable waste of time, supplies, vitality and cash—far exceeding the sources required to provide a small variety of commercial-like cells upfront.

In truth, upscaling new supplies or processes developed at laboratary scale presents a collection of challenges which can be steadily uncared for when the target is restricted to producing mAh-scale cells (that’s, with TRL ≤3)17,18. As illustrated in Fig. 1, on the way in which from particular person elements (energetic supplies, separator, electrolyte, present collector, casing and so forth) to the completed cell, issues typically come up throughout slurry mixing and coating, electrode drying and calendering, and cell meeting and formation19,20. Without having the likelihood right here to debate these challenges individually, we need to emphasize that almost all of the problems proven in Fig. 1 has a considerable impression on the battery efficiency and might be totally detected when assembling Ah-level large-area cells20. Nonetheless, based on a current peer-reviewed publication that analysed greater than 13,000 scientific publications on batteries, solely about 28% of the analysis articles reporting the electrode composition specify the realm of the electrodes21. A associated examine on the identical dataset means that even fewer precisely describe the cell format and design (for instance, coin cell, pouch cell and so forth)22.

Fig. 1: The assorted phases of electrode manufacturing and cell preparation.

Fishbone diagram displaying attainable sources of defects and points within the phases of electrode manufacturing (from 1 to 4), cell meeting (5) and formation (6).

We routinely use coin cells (roughly 2–6 mAh) to guage the particular capability, preliminary coulombic effectivity and discharge price functionality, as they’re easy and fast to assemble and take a look at. Sometimes, for an preliminary evaluation of the Li-ion storage functionality, coin cells are assembled utilizing the investigated energetic supplies on the working (constructive) electrode and lithium metallic on the counter (detrimental) electrode, together with the identical electrolyte resolution that’s utilized in upscaling experiments with bigger codecs. Nonetheless, the reliability of cycle life information obtained from coin cells is questionable, because it has been proven to depend upon extremely variable parameters, comparable to the kind of casing metal and the utilized stress, that’s, the stack height23,24, that are unbiased of the supplies studied. As well as, the misalignment of constructive and detrimental electrodes can simply occur25, and the excessive perimeter-to-area ratio of small-area electrodes signifies a powerful, detrimental affect of the electrodes’ edges on cell performance26. Whereas these points should still permit researchers to check the outcomes from coin cells assembled in related circumstances inside their laboratories, comparisons of outcomes obtained in several laboratories, the place the assembling high quality just isn’t recognized, needs to be approached with warning. Though coin cells are often the popular format for low-TRL research to characterize new battery supplies, they need to be thought-about insufficient predictors of biking stability in scaling-up research involving TRL ≥4 cells. Furthermore, high-current-rate experiments must also be critically evaluated as a result of giant resistance of the coin cell set-up and, within the case of Li metallic coin cell checks, the overpotential attributable to the lithium metallic counter/detrimental electrode, particularly when testing working/constructive electrodes with excessive areal capacity23,24.

Single-layer or double-layer pouch cells (roughly 50–200 mAh) are the next-size battery take a look at car in our workflow27. They are often conveniently assembled utilizing a comparatively small quantity of energetic materials and even hand-coated electrodes. Their bigger space permits a extra dependable evaluation of long-term biking stability28. These information can be utilized to deduce the behaviour of bigger cells, however with some essential limitations to contemplate, such because the nonetheless comparatively excessive perimeter-to-area ratio, the impression of the detrimental electrode overhang dimension on the overall cell space, and a lowered temperature improve throughout biking in contrast with Ah-scale cells12,28. As well as, pouch cells lack standardization when it comes to dimensions and space, as they don’t have a standardized exhausting case to constrain their dimension, not like cylindrical and prismatic cells. Importantly, multilayer stacked pouch cells, that’s, pouch cells whose electrodes are minimize in a number of items with identical dimensions and piled up29, don’t be certain that the electrodes used in the course of the meeting are persistently of top of the range, as solely the very best sections of the electrode could also be chosen and minimize for the cell meeting. This challenge is lowered in giant wound cells, as electrodes with lengths over 1 m are utilized in Ah-scale cells, which should meet strict manufacturing high quality requirements to make sure dependable biking information. To make sure the reproducibility of battery testing, it’s essential to assemble a related quantity of such wound cells the place the double-sided electrodes should be homogeneously coated over a size within the order of 100 m to 1,000 m (refs. 12,29). Moreover, winding induces stress on the electrodes as a result of curvature across the cell’s winding mandrel, requiring them to have extra stringent mechanical properties (for instance, adhesion and cohesion) in contrast with stacked pouch cells12,30. Wound cell codecs usually have predefined casings, comparable to 18650, 21700, 4680 and so forth, for cylindrical cells, or VDA (acronym for Verband der Automobilindustrie, the German Affiliation of the Automotive Business) PHEV1, VDA PHEV2 and so forth, for prismatic cells29. Standardized dimensions facilitate the comparability of vitality density and efficiency throughout totally different cells from numerous analysis establishments or producers. Nonetheless, they require extra superior gear for his or her meeting and biking, comparable to winding machines and high-current testing gear. You will need to discover that, for utilized testing currents >1 A, the thermal behaviour and the resistance of present collectors and cell’s connectors begin performing as hindrances for the supply of ample cell efficiency, not like in smaller cell codecs, the place such excessive currents are often not utilized.

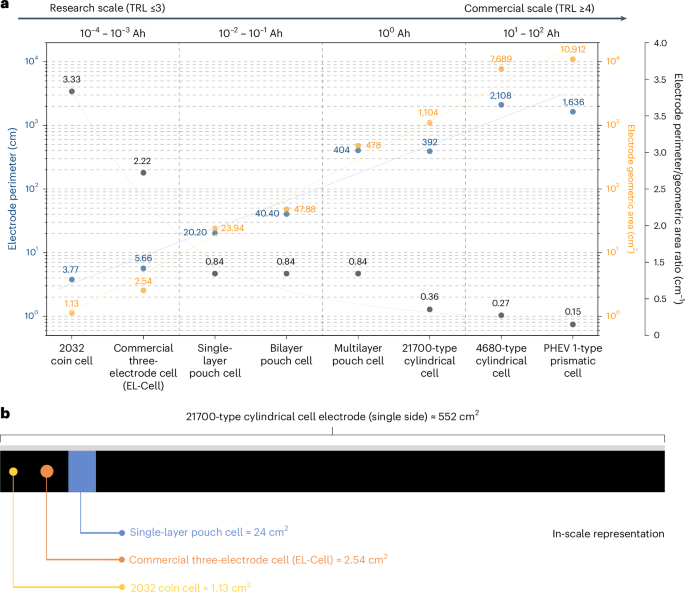

Determine 2a reveals the geometrical space and perimeter of electrodes for numerous kinds of laboratory-scale and industrial-scale cell configurations we assemble and take a look at. Transferring from the left to the proper of the graph, it may be observed how the values of electrode perimeter and geometrical space change when transitioning from fundamental low-TRL analysis to high-TRL business scale (information and strategies used to calculate the geometrical space and perimeter values for every kind of cell might be present in Supplementary Observe 1). The geometrical space and perimeter span 4 to 5 orders of magnitude when transitioning from a 2032 coin cell to a prismatic cell. Whereas only some sq. centimetres of electrode are wanted for a coin cell, business cell codecs require giant, high-quality, defect-free electrodes to achieve the meant battery efficiency and guarantee information reliability. Based mostly on the assumptions used for the calculations for Fig. 2a, 21700-cell electrodes are roughly 1 m lengthy, whereas electrodes for a 4680-cell measure greater than 5 m in size. Because of this, for constructing these large-electrode-area cells, the absence of the problems illustrated in Fig. 1 should be ensured over multiples of those electrode lengths even at pilot scale, to not point out mass manufacturing. Typically, whatever the cell format used, guaranteeing the coating of high-quality, uniform electrodes needs to be a major focus in battery analysis research, and it’s of paramount significance when aiming to provide and take a look at cells with TRL ≥4.

Fig. 2: Variation of electrode geometric areas and perimeters shifting from low-TRL to high-TRL battery analysis.

a, The electrode perimeter (blue), electrode geometric space (yellow) and perimeter/geometric space ratio (gray) for various cell codecs. Info concerning the assumed dimensions, quantity and sort of electrodes for every cell format is offered in Supplementary Observe 1. The dashed traces function a information for the eyes. b, A schematic illustration with an in-scale comparability of the scale of a typical 21700-type cylindrical cell electrode, a single-layer pouch cell electrode and disk-shaped electrodes for commercially out there three-electrode cells (EL-Cell) and 2032 coin cells. For the 21700-type cylindrical cell electrode, the realm of solely one of many two coated sides is reported, for a greater comparability with the opposite single-side coated electrodes.

To raised visualize this dimension distinction, Fig. 2b reveals a scaled comparability of a typical electrode for a 21700 cylindrical cell versus electrodes for single-layer pouch cells, commercially out there three-electrode cells (EL-Cell) and 2032 coin cells. From this schematic, it’s evident that the geometrical space of the electrodes in coin cells may be very restricted in contrast with these utilized in cylindrical cells. The identical consideration might be utilized to electrodes utilized in single-layer pouch cells. Even within the case of multilayer pouch cells assembled in a stacked configuration, a number of probably the most homogeneous detrimental and constructive electrodes remains to be attainable, as the person electrodes in small-area pouch cells are often a lot smaller than these in cylindrical or prismatic cells, the place electrodes are wound slightly than stacked30. This electrode choice for pouch cell meeting will increase the scrap price and hinders the identification of points in the course of the electrode manufacturing part. Subsequently, large-area, non-stacked cells can extra reliably be certain that the used electrodes are freed from defects that would negatively have an effect on a cell’s electrochemical vitality storage efficiency.

In Fig. 2a, we additionally present the electrode perimeter-to-geometric space ratio for every cell format, which can be utilized to evaluate the affect of electrode edges on cell behaviour. The sting area performs a crucial function within the cell’s stability as it’s a hotspot for lithium deposition on the detrimental electrode throughout battery operation31. Furthermore, slicing electrodes into the specified form can produce burrs and mud on the edges, growing the chance of piercing the separator and inflicting native quick circuits30. Subsequently, a decrease perimeter-to-geometric space ratio signifies higher electrode high quality and fewer defects. Whereas a 12-mm-diameter coin cell electrode has a perimeter-to-area ratio of three.33 cm−1, the identical ratio for a double-side coated 6 × 92 cm2 21700 cylindrical cell electrode is 0.36 cm−1, about ten instances decrease. The selection of large-area cells turns into then much more essential, because it minimizes the opposed results of edges on battery efficiency. With the detrimental impact of the electrodes’ edges, the precise efficiency of the cell won’t align with the meant efficiency, as a result of the next variety of edges will increase the probability of defects and, therefore, the opportunity of triggering of failure mechanisms. We might additionally like to emphasise that, within the case of multilayer stacked pouch cells, growing the variety of layers (and, subsequently, the capability and space) doesn’t end in a lower within the perimeter-to-geometric space ratio, as the chosen electrodes preserve the identical geometric traits.