If the previous couple of weeks have made us sure of one thing, it’s uncertainty. Provide chains are being utterly reimagined to fulfill the calls for of a brand new world. Shifting commerce insurance policies, spiking enter or commodity costs, provider dangers and logistics disruptions – you title the motive force of uncertainty – and that’s the brand new regular for the trade, making provide chains the true battleground for aggressive benefit. The actual competitors now’s between provide chains, not particular person firms.

On this new paradigm, firms should construct the muscle to repeatedly enhance customer support ranges, on-time supply efficiency, lead instances and achieve this amidst unprecedented variability and disruptions. Databricks has partnered with main firms to:

Handle sharp and sudden volatility – Addressing sudden shifts in buyer demand and inputs to optimize provide chain resilience.

Optimize capability administration – Leveraging AI-driven insights to reallocate capability and shield high-value manufacturing.

Assess provider threat – Evaluating provider reliability, monetary stability, and geopolitical publicity to mitigate disruptions and guarantee continuity of provide.

Enhance profitability – Utilizing unified knowledge analytics to steadiness order success, monetary influence, and operational effectivity.

The place Conventional Provide Chain Tech Falls Quick

Regardless of vital developments in expertise, many firms nonetheless face persistent challenges that hinder their provide chain efficiency. Most firms are dealing with:

On-Time Supply Efficiency Points: On-time supply and on-time in full efficiency are essential success components, with poor efficiency resulting in extreme monetary penalties, penalties and buyer dissatisfaction.

Planning-Execution Gaps: A widening hole between planning and execution as disruptive occasions in provide chains have elevated tenfold, making earlier enterprise planning approaches out of date – and requiring accelerated resolution making cycles.

Guide Processes: Prevalence of conventional, error-prone guide processes that result in missed gross sales alternatives and cargo delays requiring a shift in the direction of AI-augmented, automated techniques that present real-time insights.

Sustainability Pressures: The absence of a complete technique for emissions knowledge within the provide chain as demand for low-carbon services and products is remodeling sustainability from a threat mitigation technique to a robust revenue driver, with prospects prepared to pay a premium for sustainable choices.

To handle the enterprise challenges and capitalize on market alternatives, firms should deal with optimizing their provide chains by means of data-driven options, AI-driven automation, and strong emissions monitoring throughout their whole worth chain.

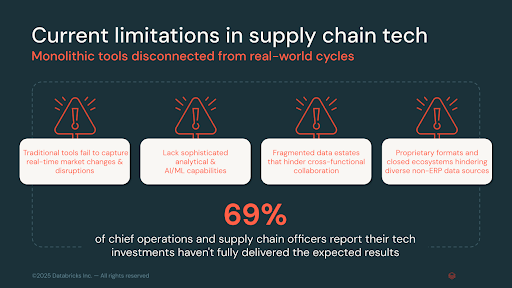

Nevertheless, conventional demand planning and enterprise software program face a number of challenges:

Reliance on historic knowledge and periodic reporting, failing to seize real-time market adjustments and disruptions

Prevalence of proprietary, closed ecosystems hindering knowledge integration from numerous sources to reinforce provide chain planning and execution

Lack of subtle analytical capabilities and machine studying algorithms essential to enhance knowledge high quality, complicated demand forecasting and provide chain optimization

Absence of efficient knowledge collaboration instruments, resulting in fragmentation and inconsistent knowledge throughout departments

Therefore, it is no shock that 69% of operations and provide chain officers say their tech investments have not absolutely delivered the anticipated outcomes (PwC’s 2024 Digital Traits in Operations Survey). Chief Provide Chain Officers (CSCOs) are more and more transferring away from these inflexible options, in search of extra open and versatile platforms that supply a holistic view of your entire provide chain and allow real-time, data-driven optimization.

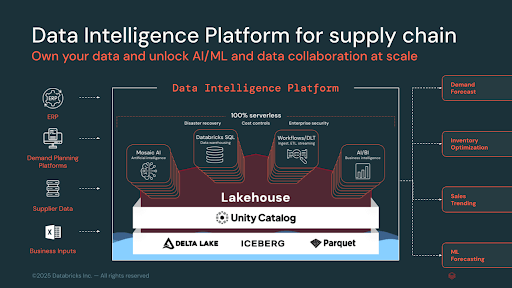

Introducing Databricks Information Intelligence Platform for Provide Chain

Your provide chain is as distinctive as your organization. Why accept a best-guess approximation resolution by somebody who does not know what you are promoting? Construct your individual distinctive capabilities with the Information Intelligence Platform.

Manually creating reviews to handle each provide chain question is not possible or environment friendly. The sheer quantity and velocity of knowledge from world suppliers, logistics companions, and buyer touchpoints demand a extra scalable and dynamic strategy to provide chain analytics.

Databricks affords a complete suite of instruments and applied sciences to revolutionize provide chain administration by means of data-driven insights and AI-powered options.

Databricks SQL and AI/BI Genie empower provide chain analysts by enabling pure language queries and AI-assisted SQL coding, making knowledge accessible to everybody within the group.

Mosaic AI’s Multi Mannequin Forecasting framework accelerates large-scale forecasting and planning, essential for gross sales, stock and demand predictions.

Mosaic AI Agent Framework supplies the flexibility to develop agentic apps that drive autonomous provide chain actions, guaranteeing correct, protected, and ruled AI purposes.

Unity Catalog Delta Sharing and Clear Rooms facilitate safe knowledge collaboration with companions, whereas the Databricks Market affords entry to useful third-party knowledge to reinforce provide chain analytics.

These built-in options allow companies to make sooner, extra knowledgeable choices and optimize their provide chain operations in an more and more complicated and data-driven surroundings.

Actual-World Success Tales

Shell makes use of Databricks globally to optimize its $1 billion spare half stock and scale back downtime throughout upstream & downstream operations globally, offering stock analysts with suggestions on optimum spare half ranges for 3,000 supplies throughout 50 places.

Volvo makes use of Databricks to realize real-time visibility into their large stock of over 700,000 components, enabling them to effectively distribute these components worldwide, throughout your entire chain, from provider to truck vendor.

Walgreens leveraged Databricks to optimize their provide chain throughout almost 9,000 retailer places, saving hundreds of thousands of {dollars} by right-sizing stock ranges. They now course of 40,000 knowledge occasions per second, enabling correct stock forecasting and rising productiveness by 20%. This has allowed pharmacists to keep away from costly out-of-stock conditions and spend extra time offering customized care to sufferers.

A number one paints and coating firm leverages Databricks to automate provide chain forecasting course of and acquire larger visibility into demand drivers, rising demand forecast accuracy by 12%, saving of $35M+ in stock and eliminating $500K+ in overstocking prices per enterprise unit.

Williamsa pure gasoline infrastructure firm, standardized on Databricks to energy prime quality datasets for certifying low-emission gasoline. streamlining knowledge integration from end-to-end manufacturing processes resembling sourcing, manufacturing, transportation and distribution, and enabling environment friendly sharing with certification companions. Williams decreased TCO by 40% and was capable of monetize their decarbonization efforts, producing $6 million in margin from promoting licensed low-emission gasoline, whereas additionally advancing their purpose of decreasing baseline emissions by 50% by 2030.

HP’s 3D Print division makes use of Databricks’ Delta Sharing and AI instruments to supply prospects with real-time telemetry knowledge on their 3D printing gear, enabling proactive upkeep, optimized operations, and decreased prices in the end boosting buyer satisfaction and operational effectivity.

Databricks Answer Accelerators

Distribution Optimization: Optimize transportation prices, predict supply-demand, and enhance distribution community efficiency with pre-built instruments.

Databricks Intelligence Platform for IoT: Utilizing sensor knowledge, machine studying, and GenAI brokers to optimize manufacturing operations.

Security Inventory Administration: Optimize stock ranges throughout the availability chain utilizing machine studying to reduce extra inventory, scale back prices, and enhance monetary flexibility.

Demand Forecasting: Carry out demand forecasting on the half stage slightly than the mixture stage to reduce disruptions in your provide chain and enhance gross sales, whereas successfully managing materials shortages and avoiding overplanning.

Route Optimization: Optimize supply routes, enhance profitability, and improve effectivity in logistics operations.

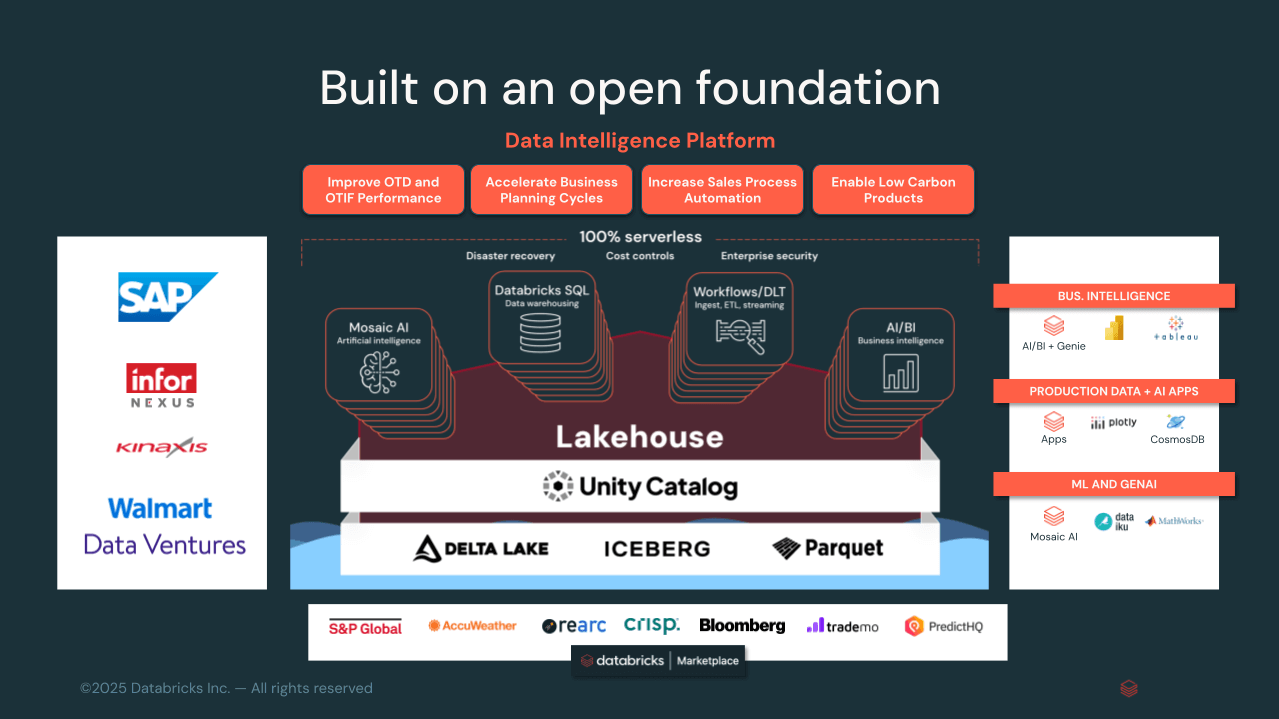

Rising Associate Answer Ecosystem

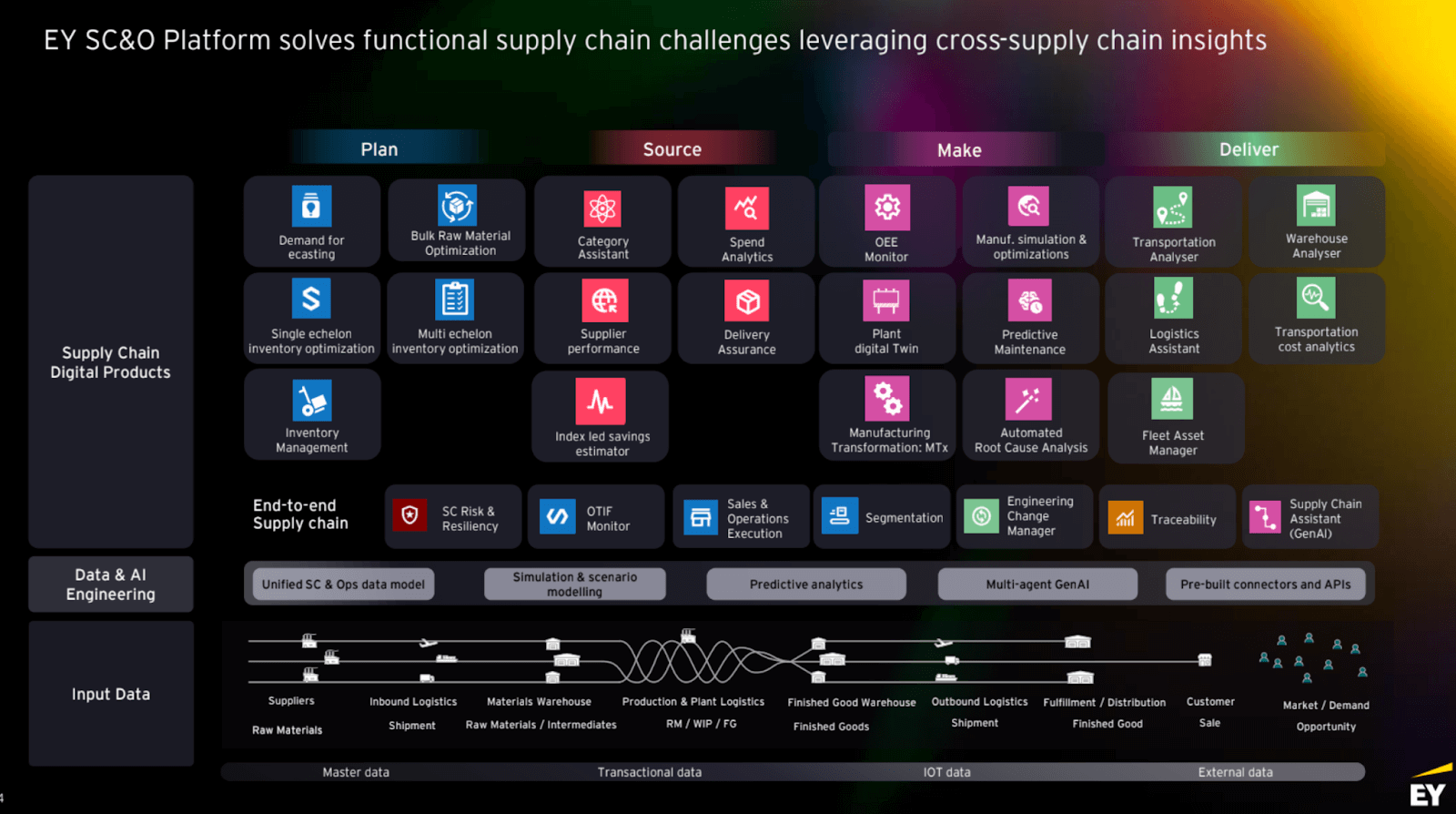

We’re excited to have SAP, Infor Nexus and Kinaxis as expertise companions, bridging provide chain and enterprise resolution makers extra successfully. As well as, prospects can now enrich their provide chain analytics and AI use instances with proprietary and open datasets from main knowledge suppliers resembling S&P International, Accuweather, Bloomberg, Crisp, rearc, Altana, trademo and PredictHQ. Unveiled at NVIDIA GTC 2025, Ernst & Younger’s next-generation digital provide chain and operations resolution is constructed on the strong basis of the Databricks Information Intelligence platform and will increase provide chain resiliency in opposition to disruptions and affords well timed insights by means of integration with current techniques.

Remodel with Information Intelligence

Do not miss this chance to revolutionize your provide chain administration and keep forward in at present’s aggressive enterprise panorama. Meet us on the upcoming Gartner Provide Chain Symposium to dive deeper into options to form the way forward for digital provide chains.