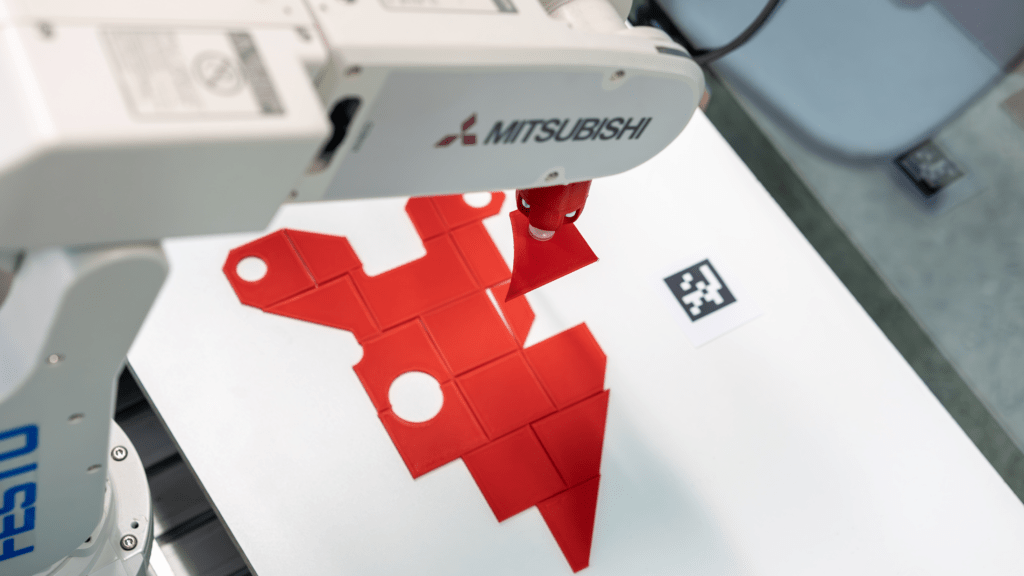

Decide-and-Place functions are a central space of software for robotics. They’re usually utilized in business to speed up meeting processes and scale back handbook actions – an thrilling subject for laptop science masters of the Institute for Knowledge -optimized manufacturing of the Kempten College. They developed a robotic that optimized processes by using synthetic intelligence and laptop imaginative and prescient. Based mostly on an meeting drawing, the system is ready to seize particular person elements and to place them off at a given level – akin to a puzzle. Then the elements could be glued manually there by an worker.

Decide-and-Place robots positioned elements much like a puzzle. (© Kempten College)

Two IDS industrial cameras present the mandatory picture data

With the assistance of two Ueye XC cameras and a AI-based picture processing, the system analyzes the atmosphere and calculates exactly recording and storage coordinates. One of many cameras was positioned above the work floor, the opposite above the withdrawal level. Particularly, a AI pipeline processes the images of the 2 cameras in a number of steps to find out the precise location and alignment of the objects. With the assistance of the pc imaginative and prescient algorithms and neuronal networks, the system acknowledges related options, calculates the optimum gripping factors and generates exact coordinates for the absorption and storage of the objects. As well as, the system clearly identifies the elements by segmenting their floor and evaluating the contours with a database. As well as, it makes use of the outcomes to allow an approximation to already saved elements. The automation answer thus reduces the dependence on skilled data, shortens course of instances and counteracts the scarcity of expert employees.

Robotic grabs particular person elements and positions them at a given place. (© Kempten College)

Robotic grabs particular person elements and positions them at a given place. (© Kempten College)

Digicam necessities

Interface, sensor, dimension and worth have been the factors that have been decisive for the selection of the digital camera mannequin. The Ueye XC combines the consumer -friendliness of a webcam with the efficiency of an industrial digital camera. It solely requires a cable connection for operation. Outfitted with a 13-MP-On-Semi sensor (AR1335), the autofocus digital camera delivers high-resolution photos and movies. An interchangeable macro attachment lens permits a shortened object distance, which implies that the digital camera can also be appropriate for close-range functions. Their integration was additionally quite simple, akin to Raphael Seliger, analysis assistant at Kempten College of Utilized Sciences, explains: “We tie the cameras to our Python Backend by way of the IDS Peak interface.”

Two Ueye XC industrial cameras present the mandatory picture data. (© Kempten College)

Two Ueye XC industrial cameras present the mandatory picture data. (© Kempten College)

outlook

Sooner or later, the system is to be additional developed by re -forcement studying – a way of machine studying based mostly on studying by experiments and errors. “We want to develop the AI capabilities to make the pick-and-place processes extra intelligently. Below sure circumstances, we want an extra digital camera instantly on the robotic arm,” explains Seliger. An automated accuracy examine of the saved elements can also be deliberate. In the long run, the robotic ought to be capable to perform all vital steps independently based mostly solely on the meeting drawing.

I prefer it:

I like it’s loaded …